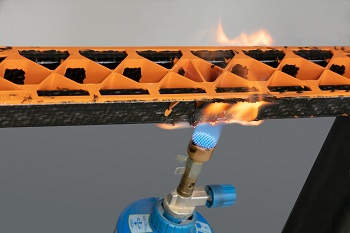

Tepex continuous-fiber-reinforced thermoplastic composites from Lanxess are characterized by their high inherent flame-retardant properties. One of the reasons for this is their high fiber content. They therefore already pass many of the flammability tests required for typical applications without flame protection. However, for some applications - such as housings for control cabinets or components of high-voltage batteries for electric vehicles - a V-0 classification in the UL 94 flammability test from the US testing institute Underwriters Laboratories Inc. is often mandatory. For such cases, Lanxess has developed three new halogen-free, flame-retardant Tepex variants with a polyamide 6 matrix. “These structural materials are the material of choice when a V-0 classification is required and the components need to have a very high degree of strength, rigidity and energy absorption at the same time,” explains Sabrina Anders, Project Manager at the Lanxess subsidiary Bond-Laminates in Brilon, Germany, where Tepex is developed and produced.

Three product variants available

Tepex dynalite 102fr-RG600(x)/47% is reinforced with roving glass fibers. These can also be arranged multiaxially and thus precisely matched to the load transfer points and load paths in the component. The composite is universally applicable and is suitable for high-voltage components of electric vehicle batteries, such as separator plates, cover plates and control unit housings. In contrast, Tepex dynalite 102fr-FG290 is targeted at applications in the electrical and electronics sector. With its reinforcement of fine glass fiber, it produces high-quality surfaces that are easy to paint. It is suitable, for example, for small housings that are required to comply with the DIN EN 45545-2 standard, “Railway applications - Fire protection on railway vehicles”. Tepex dynalite 202fr is reinforced with carbon fibers and is intended for components subjected to extreme mechanical stress, such as high-strength electronic housings. According to Anders, “It is an alternative to composites made of flame-retardant polycarbonate if their strength and rigidity are not sufficient, for example.”

Mechanical properties match those of standard products